Solid-State vs. Semi-Solid-State Batteries: Key Differences & UAV Applications

Introduction

Traditional lithium-ion batteries (low energy density, flammability) fall short for drones—especially agricultural plant protection UAVs needing longer flight times and safety. Solid-state (SSBs) and semi-solid-state (Semi-SSBs) batteries offer solutions; below is their core distinction and use cases.

Core Differences

The key gap lies in electrolyte design, shaping performance and viability:

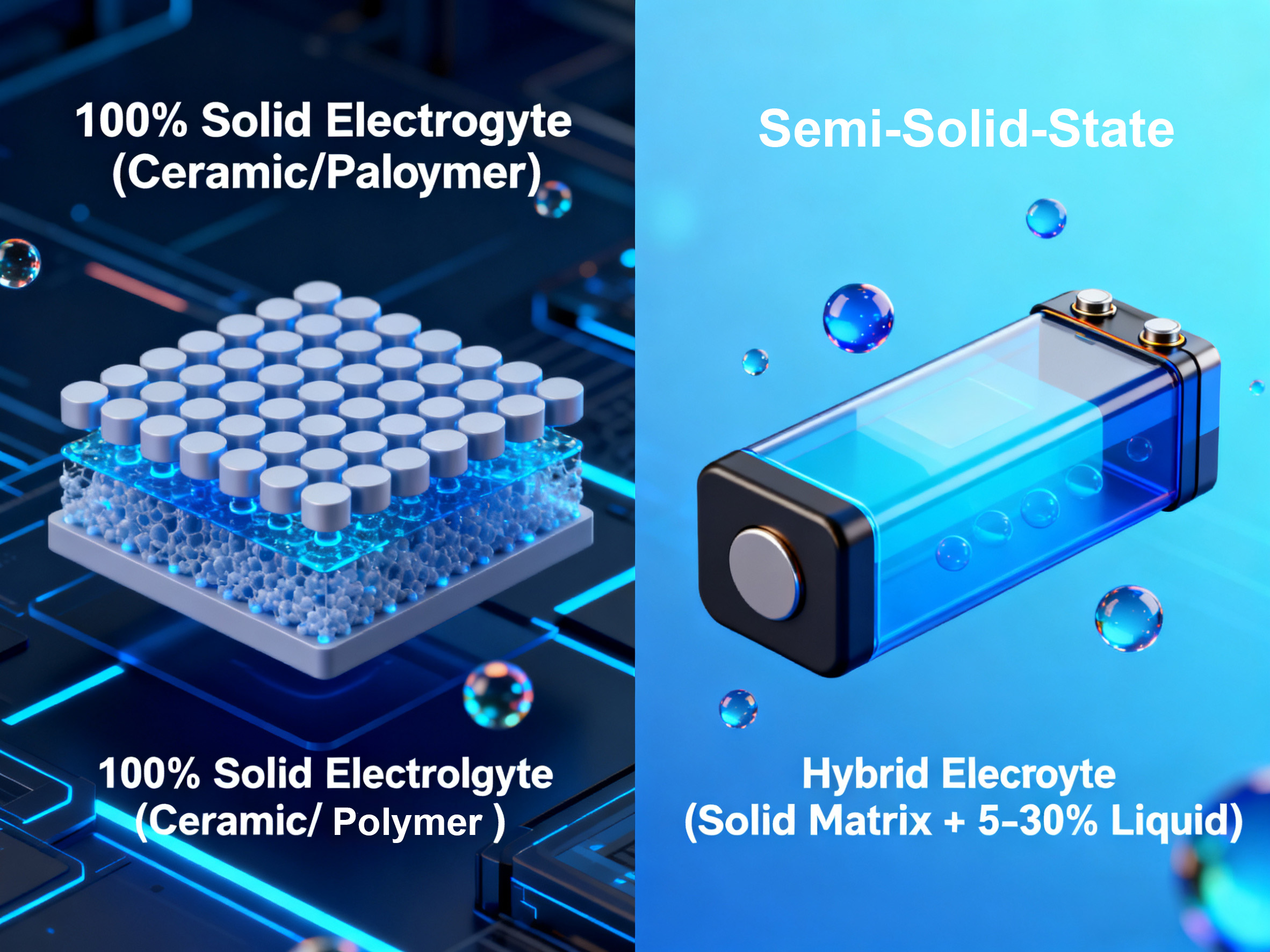

1. Electrolyte

- SSBs: Adopt 100% solid electrolytes (e.g., ceramic, polymer) with no flammable liquid components.

- Semi-SSBs: Use a hybrid electrolyte—combining a solid matrix with 5–30% liquid electrolyte—to balance performance and simplicity.

2. Key Performance

In key performance indicators, the two technologies show clear differences:

- Energy Density: SSBs reach 300–400+ Wh/kg (even up to 500 Wh/kg in prototypes), while Semi-SSBs stand at 250–350 Wh/kg.

- Safety: SSBs have zero leakage and thermal runaway risks; Semi-SSBs feature low flammability, which is safer than traditional lithium-ion batteries but still has slight leakage potential compared to SSBs.

- Charging Speed: SSBs support 15–30 minutes of fast charging, and Semi-SSBs are faster (10–25 minutes) than most current SSBs.

- Cycle Life: SSBs offer 1,000–3,000 cycles, while Semi-SSBs have a shorter cycle life of 800–2,000 cycles.

- Cost & Scalability: SSBs have high costs and are in the pre-commercial stage; Semi-SSBs are more cost-effective and near commercialization.

- Temperature Tolerance: SSBs adapt to a wide range (-40°C to 85°C) for extreme environments, and Semi-SSBs work in a moderate range (-20°C to 75°C) suitable for most use cases.

3. Structure Impact

SSBs have a thinner, lighter design—critical for reducing UAV weight—thanks to no gaps from liquid electrolytes. Semi-SSBs retain slight bulk due to the hybrid electrolyte but offer better flexibility for custom UAV battery packs.

Applications in Drones & Agricultural UAVs

1. Agricultural Plant Protection UAVs

- Semi-SSBs: Currently the mainstream choice—extends flight time to 30–45 minutes (vs. 15–20 minutes for lithium-ion batteries), covers 10–15 acres per mission, supports 20-minute fast charging, and has low crop contamination risk from leakage.

- SSBs: Target high-end scenarios—prototypes with 400 Wh/kg energy density enable 60–90 minutes of flight (covering 20–30 acres per mission) and adapt to extreme climates, but 3–5x higher costs limit widespread use.

2. Commercial/Industrial Drones

- Semi-SSBs: Fit mid-range tasks (e.g., surveying, inspection) with 25–35 minutes of flight time and over 1,200 cycles, ensuring cost-effectiveness for frequent operations.

- SSBs: Suit high-performance needs (e.g., long-range mapping) with 50–80 minutes of flight time and zero fire risk, making them ideal for operations over urban or sensitive areas.

3. Consumer Drones

- Semi-SSBs: Upgrade flight time by 30–40% and are cost-friendly, suitable for entry-level to mid-range models.

- SSBs: Serve niche premium use (e.g., professional photography) with 45+ minutes of flight time and enhanced safety.

Future & Conclusion

Semi-SSBs will dominate UAV markets in 5–7 years due to cost and scalability advantages. As SSB manufacturing technology improves (e.g., scalable ceramic electrolyte production), they will gradually penetrate high-end segments. Both technologies solve the limitations of traditional lithium-ion batteries, unlocking longer, safer drone operations in agriculture, logistics, and more.

If you require semi-solid batteries, ULi can offer a wide range of solutions. Please feel free to contact us.

Post time: Oct-24-2025