As the global demand for high-performance, safe, and long-lasting energy storage solutions surges—driven by electric vehicles (EVs), consumer electronics, renewable energy integration, and beyond—traditional lithium-ion batteries (LIBs) are approaching their performance limits. Liquid electrolytes, the core component of conventional LIBs, pose inherent risks of leakage, thermal runaway, and limited energy density. Enter semi-solid-state and solid-state batteries (SSBs): the transformative technologies that are redefining the future of energy storage. This article traces the evolution from semi-solid-state to solid-state batteries, exploring their technical breakthroughs, advantages, and the path toward widespread adoption.

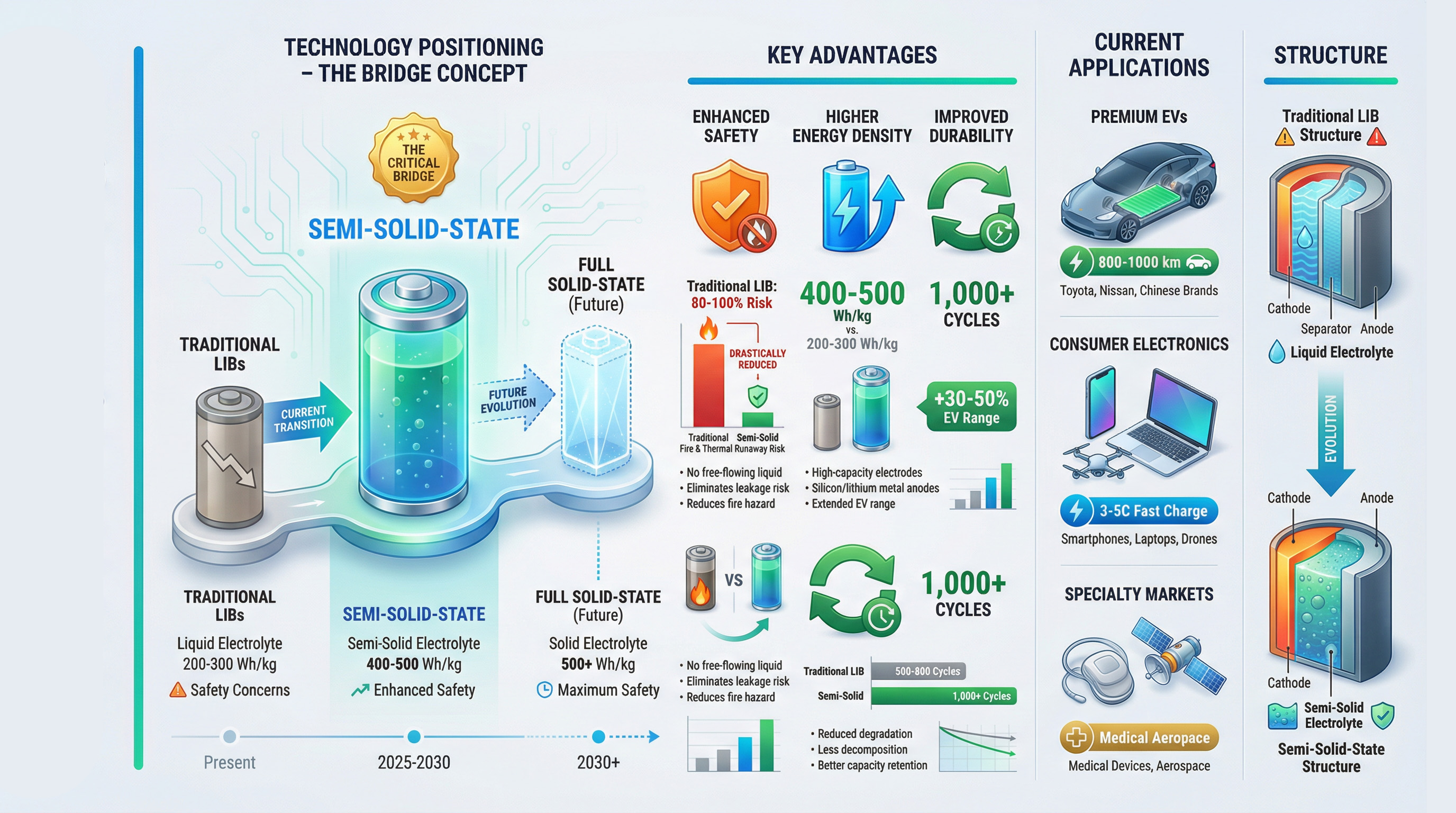

1. Semi-Solid-State Batteries: The Critical Bridge

Semi-solid-state batteries represent the first major leap beyond traditional LIBs, blending the reliability of mature lithium-ion technology with the safety and performance of solid-state design.

What Are Semi-Solid-State Batteries?

Unlike conventional LIBs that use flammable liquid electrolytes, semi-solid-state batteries employ semi-solid electrolytes—typically polymer gel electrolytes, ceramic-polymer composites, or thickened liquid electrolytes with solid fillers. These electrolytes retain partial fluidity while eliminating free-flowing liquid, striking a balance between technical feasibility and performance improvement.

Key Advantages Over Traditional LIBs

- Enhanced Safety: The absence of free liquid electrolytes drastically reduces leakage, fire, and thermal runaway risks—addressing the biggest pain point of conventional EV and consumer electronics batteries.

- Higher Energy Density: Semi-solid electrolytes enable compatibility with high-capacity electrodes (e.g., silicon-based anodes, high-nickel cathodes) that were previously limited by liquid electrolyte instability. Energy density reaches 400–500 Wh/kg (vs. 200–300 Wh/kg for traditional LIBs), extending EV range by 30–50% or doubling the runtime of portable devices.

- Improved Durability: Reduced electrode degradation and electrolyte decomposition result in longer cycle life (1,000+ charge-discharge cycles) and better retention of capacity over time.

Current Applications

Semi-solid-state batteries are already transitioning from lab to commercial use:

- Premium EVs: Automakers like Toyota, Nissan, and domestic Chinese brands are integrating semi-solid packs into high-end models, delivering 800–1,000 km of range per charge.

- Consumer Electronics: High-end smartphones, laptops, FPV and drones are adopting semi-solid batteries for faster charging (3C–5C rates) and safer operation.

- Specialty Markets: Medical devices (e.g., implantable sensors) and aerospace equipment benefit from their compact size, low risk, and stable performance.

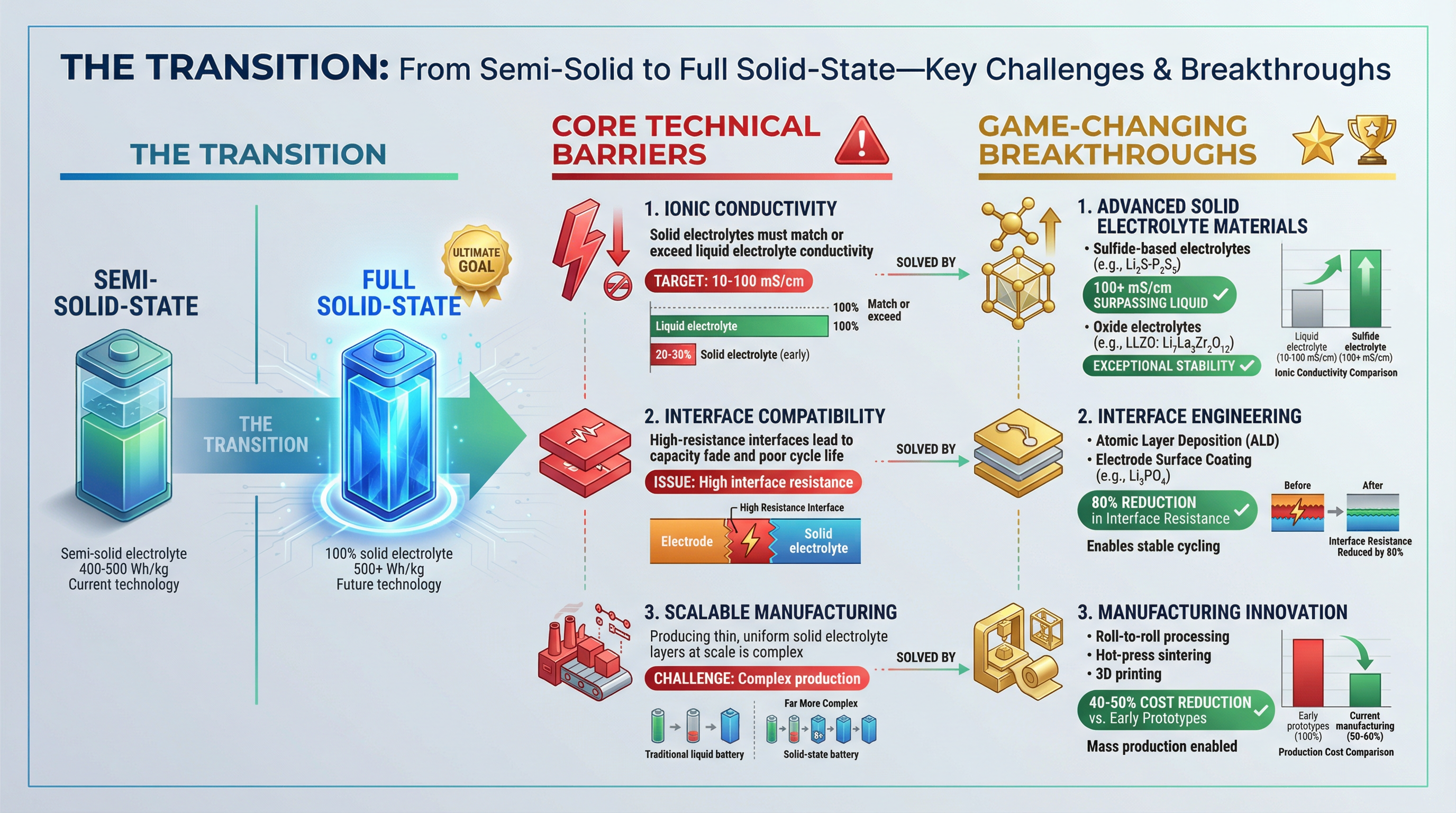

2. The Transition: From Semi-Solid to Full Solid-State—Key Challenges & Breakthroughs

The ultimate goal of battery innovation is full solid-state technology, which replaces semi-solid electrolytes with 100% solid electrolytes (e.g., sulfide, oxide, or polymer-based materials). This transition addresses the remaining limitations of semi-solid systems but requires overcoming critical technical hurdles:

Core Technical Barriers

- Ionic Conductivity: Solid electrolytes must match or exceed the ionic conductivity of liquid electrolytes (10–100 mS/cm) to ensure efficient charge transfer.

- Electrode-Electrolyte Interface Compatibility: Solid electrolytes tend to form high-resistance interfaces with electrodes, leading to capacity fade and poor cycle life.

- Scalable Manufacturing: Producing thin, uniform solid electrolyte layers and integrating them with electrodes at scale is far more complex than liquid electrolyte assembly.

Game-Changing Breakthroughs

- Advanced Solid Electrolyte Materials: Sulfide-based electrolytes (e.g., Li2S-P2S5) now achieve ionic conductivities of 100+ mS/cm—surpassing liquid electrolytes—while oxide electrolytes (e.g., LLZO: Li7La3Zr2O12) offer exceptional stability.

- Interface Engineering: Techniques like atomic layer deposition (ALD) and electrode surface coating (e.g., Li3PO4 thin films) reduce interface resistance by 80%, enabling stable cycling.

- Manufacturing Innovation: Roll-to-roll processing, hot-press sintering, and 3D printing are being adapted to mass-produce solid-state cells, lowering production costs by 40–50% compared to early prototypes.

3. Solid-State Batteries: The Future of Energy Storage

Full solid-state batteries represent the pinnacle of current energy storage technology, unlocking unprecedented performance and safety.

Defining Features of Solid-State Batteries

- 100% Solid Electrolytes: No liquid components whatsoever—eliminating all leakage and thermal runaway risks, even under extreme conditions (e.g., puncture, overcharging).

- Unmatched Energy Density: With compatibility with lithium-metal anodes (the “holy grail” of battery design) and high-voltage cathodes, solid-state batteries achieve 600–800 Wh/kg—enabling EVs to travel 1,200+ km per charge and portable devices to run for days without recharging.

- Broad Temperature Adaptability: Stable performance across -40°C to 80°C, making them ideal for cold climates, industrial environments, and aerospace applications.

- Exceptional Longevity: Cycle life exceeds 2,000 cycles (vs. 1,000 cycles for semi-solid and 500–800 for traditional LIBs), reducing total cost of ownership for EVs and储能 systems (ESS).

Future Application Horizons

- Mass-Market EVs: By 2030, solid-state batteries are expected to dominate mid-to-high-end EV markets, driving down charging times to 10–15 minutes (10C fast charging) and eliminating range anxiety.

- Grid-Scale Energy Storage: Their long cycle life and safety make them perfect for storing renewable energy (solar/wind), addressing intermittency and stabilizing power grids.

- Advanced Mobility: Electric aircraft, long-haul trucks, and autonomous vehicles will rely on solid-state batteries for their high energy density and reliability.

- Micro-Electronics: Miniaturized solid-state cells will power next-gen wearables (e.g., implantable medical devices, flexible electronics) with ultra-compact form factors.

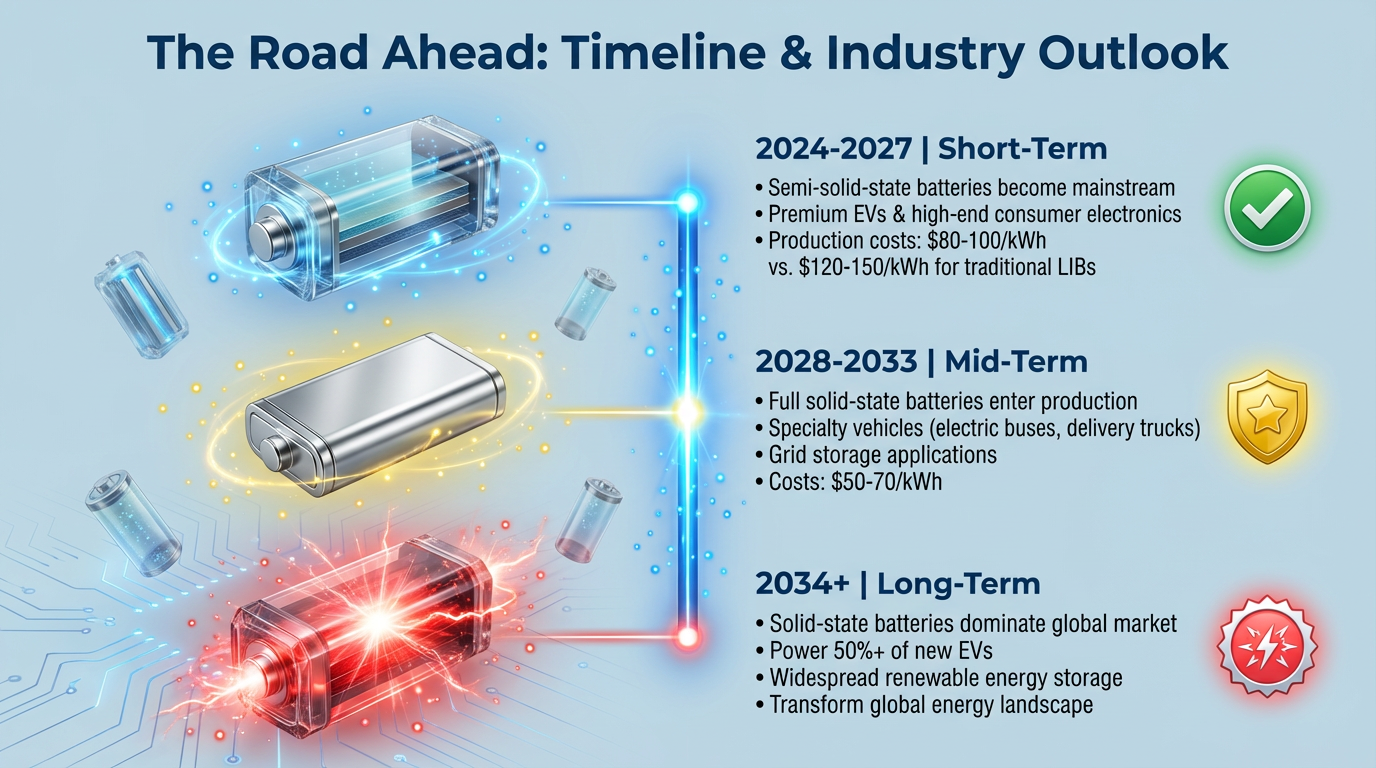

4. The Road Ahead: Timeline & Industry Outlook

The evolution from semi-solid to solid-state batteries is accelerating, with a clear roadmap for commercialization:

- Short-Term (2024–2027): Semi-solid-state batteries will become mainstream in premium EVs and high-end consumer electronics, with production costs falling to 100 per kWh (vs. 150 for traditional LIBs).

- Mid-Term (2028–2033): Full solid-state batteries will enter small-scale production for specialty vehicles (e.g., electric buses, delivery trucks) and grid storage, with costs dropping to 70 per kWh.

- Long-Term (2034+): Solid-state batteries will dominate the global battery market, powering 50%+ of new EVs and enabling the widespread adoption of renewable energy storage—transforming the global energy landscape.

5. Partner With Us for Next-Generation Battery Solutions

At ULi Power, we are at the forefront of semi-solid and solid-state battery innovation, leveraging cutting-edge materials science and manufacturing expertise to deliver customized energy storage solutions. Whether you need high-performance semi-solid packs for EVs, compact solid-state cells for consumer electronics, or scalable systems for grid storage, our team of engineers will tailor solutions to your specific requirements.

To learn more about how our semi-solid and solid-state battery technologies can drive your business forward, contact us today:

- Email: info@uli-power.com

- Phone: +86 18565703627

Join us in shaping the future of energy storage—where safety, performance, and sustainability converge.

Post time: Dec-25-2025